3. COMPETENT FORKLIFT OPERATOR TRAINING

COURSE OUTLINE OF: COMPETENT FORKLIFT OPERATOR TRAINING

Course Duration: 16 hrs

Training Methods: Class Room / Notes / Videos / Practical Driving / Post Test Assessment Theory / Practical Assessment

Who Should Attend: Forklift Drivers & Warehouse Supervisor

Conducted by: Mr RA-VR

All candidates for Forklift Operator shall meet the following basic requirements;

Candidates must have the following PPE during the 2nd Day of Training

Safety Helmets & Safety Boots

Equipment needed during the 2nd Day of Training;

1 to 3 ton Forklift / 16pcs 55 gallon drum / 2 pcs 3x4 pallet / empty space of 50 X 50 feet

PURPOSE & OBJECTIVE:

Forklifts are now very widely used in the Industries and Forklift related accidents are on the increase day by day. One of the requirements of OSHA is that all workers who operators any kind of equipment’s must be trained and they shall be competent to operate the equipment. Statistic of accident in the world relating to Forklift accidents shows that 90% of the accidents are related to Unsafe Acts or Behavioral Safety.

The purpose of this program is to create and awareness among Forklift Operators on causes of accidents with relation to Forklift operation and create a batch of Safe and Competent Forklift Drivers and certify them thus creating a safe environment around the forklift operation.

After attending this workshop, participants will be able to describe;

Course Contents

Day 1

Day 2

Course Duration: 16 hrs

Training Methods: Class Room / Notes / Videos / Practical Driving / Post Test Assessment Theory / Practical Assessment

Who Should Attend: Forklift Drivers & Warehouse Supervisor

Conducted by: Mr RA-VR

All candidates for Forklift Operator shall meet the following basic requirements;

- Must have no adverse vision problems that cannot be corrected by glasses or contacts.

- No adverse hearing loss that cannot be corrected with hearing aids.

- No physical impairments that would impair safe operation of the Forklift.

- No neurological disorders that affect balance or consciousness.

- No psychological disorders.

- Not taking any medication that affects perception, vision, or physical abilities.

- Must be able to understand Bahasa Malaysia

Candidates must have the following PPE during the 2nd Day of Training

Safety Helmets & Safety Boots

Equipment needed during the 2nd Day of Training;

1 to 3 ton Forklift / 16pcs 55 gallon drum / 2 pcs 3x4 pallet / empty space of 50 X 50 feet

PURPOSE & OBJECTIVE:

Forklifts are now very widely used in the Industries and Forklift related accidents are on the increase day by day. One of the requirements of OSHA is that all workers who operators any kind of equipment’s must be trained and they shall be competent to operate the equipment. Statistic of accident in the world relating to Forklift accidents shows that 90% of the accidents are related to Unsafe Acts or Behavioral Safety.

The purpose of this program is to create and awareness among Forklift Operators on causes of accidents with relation to Forklift operation and create a batch of Safe and Competent Forklift Drivers and certify them thus creating a safe environment around the forklift operation.

After attending this workshop, participants will be able to describe;

- accidents and what is meant by Behavioral Safety

- safety & health regulations that cover Forklift Operation in Malaysia

- the Requirements of an Employer and an Employee in Forklift Operation.

- the different types of Lifting Trucks and their capabilities.

- the different parts of the Forklift.

- the different safety features of the Forklift.

- the hazards the Forklift pose.

- the Forklift operations Do’s and Don’ts.

- the most important Safety Device in the Forklift.

- the pre-operation inspection.

- the Safety precautions needed during Refueling & Recharging of the Forklift.

- the safe operation of forklift.

Course Contents

Day 1

- Behavior Based Safety (BBS)

- Unsafe Condition

- Unsafe Acts

- Breaking the unsafe behavior

- Regulations

- Employer Responsibility

- Employee Responsibility

- 8 key Requirements of an Employer for Safe Forklift Operation.

- 3 key Responsibilities of an Employee for a Safe Forklift Operation.

- Safe Forklift Operation

- Types of Lift Truck

- Capabilities of a Forklift Truck

- Key Parts of a Lift Truck

- Safety Precautions

- Pre-operation

- Daily Pre-operation Inspection

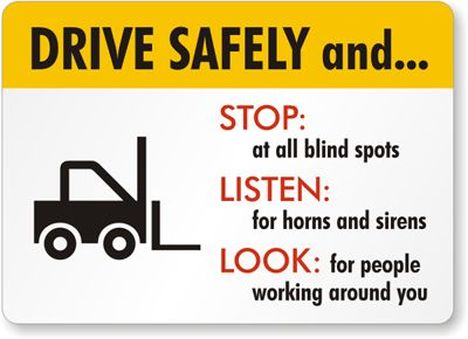

- During Operation

- Work & Safety Ethics

- Post Operation

- Daily Post Operation Inspection

- Refueling / Recharging

- Safe Maneuvering Techniques

- Loading, Unloading; On Racks & Trucks

- Forklift Stability

- Prevention of Truck Tip Over

- Personal Protective Equipment

- Other Safety Precautions

- Pre-operation

- Theory Test

- Safety Video Presentation

Day 2

- Practical Session

- Practical Forklift Inspection

- Driving in obstacle

- Driving with load in obstacle

- Loading and unloading

- Reversing through obstacle